OLTC (On Load Tap Changer) parts are used in transformers to regulate voltage while the transformer is energized.

OLTC Parts

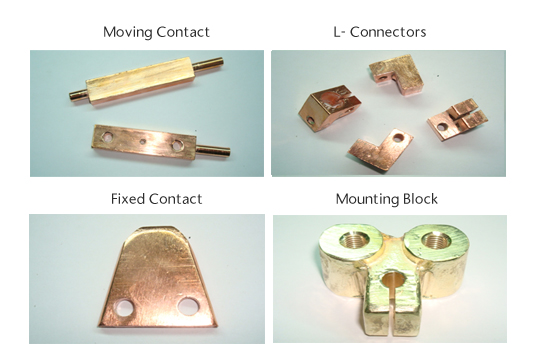

Mounting Block

The mounting block is an essential component in an On-Load Tap Changer (OLTC). It is crafted from forging superior quality brass rods to ensure durability and reliability. The mounting block is affixed to phase boards, which are made from high-quality insulating materials, using a connecting stud. The total number of mounting blocks in an OLTC varies based on the OLTC’s rating, ensuring it meets the specific electrical requirements.

Fixed Contact

Fixed contacts are critical for establishing electrical connections in an OLTC. These contacts are made from electrolytic grade copper bars, known for their excellent conductivity. To enhance durability and performance, the fixed contact is tipped with Copper Tungsten, which is known for its high resistance to wear and electrical erosion. This ensures a reliable and efficient contact point within the OLTC system.

Moving Contacts

Moving contacts are also made from electrolytic grade copper bars and are tipped with Copper Tungsten for improved durability and performance. The primary function of the moving contact is to establish a connection between the fixed contact and the collector ring. This dynamic component ensures that the OLTC can change positions effectively, maintaining a stable and reliable electrical connection.

Collector Ring

The collector ring plays a crucial role in the OLTC, particularly in facilitating the rotation of the moving contact. For a 33KV OLTC, the collector ring is made of brass, while for a 66KV OLTC, a copper ring is used. The material choice depends on the voltage level to ensure optimal performance. The collector ring serves as the main contact point upon which the moving contact rotates when the OLTC position is changed. Typically, there are three collector rings in each OLTC, ensuring balanced and efficient operation.

L-Connector Assembly

The L-connector assembly is an integral part of connecting the OLTC to the transformer. It consists of two L-shaped copper pieces and two flexible copper V-bend strips. The L-connectors are made from L-shaped copper bars, while the V-bend strips are crafted from plain copper strips. This assembly ensures a secure and flexible connection between the OLTC and the transformer, facilitated by the use of epoxy boards for enhanced insulation and durability.

FAQ’s

What OLTC components do you manufacture?

We manufacture OLTC mounting blocks, fixed contacts, moving contacts, collector rings and connector assemblies.

Are OLTC parts manufactured as per specifications?

Yes, OLTC parts are manufactured as per technical drawings and required tolerances.

Where are OLTC parts manufactured?

All OLTC parts are manufactured at our Mumbai, India manufacturing unit.

Which transformers use OLTC parts?

OLTC parts are used in power and distribution transformers requiring voltage regulation during operation.