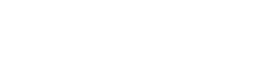

A fabricated busbar is a custom-designed copper or aluminum conductor used to distribute electrical power efficiently within electrical panels and transformer systems.

Fabricated Busbar

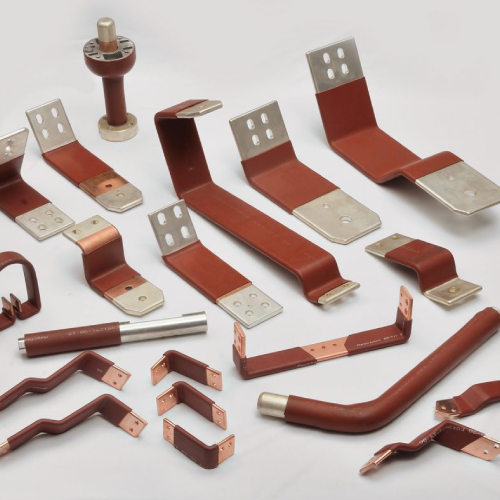

In electrical power distribution, fabricated busbars are essential components that ensure efficient and safe electricity conduction. These thick strips of copper or aluminium are crucial for the internal connections within switchboards, distribution boards, substations, or other electrical apparatus.

Key Features and Applications

- Conductivity and Structure: Busbars are designed to conduct electricity effectively, whether they are exposed or enclosed within a system. They often feature multiple joints to ensure proper length and configuration, with various take-off points connected to end-use equipment.

- Material Choice: Copper and aluminium are preferred materials due to their excellent electrical conductivity. Copper, in particular, requires specialized skills for fabrication due to its softness compared to steel.

Importance of Busbar Size

The size of a busbar is critical in determining the maximum current it can safely carry. Proper sizing ensures that the busbar can handle the required electrical load without overheating or suffering damage.

Our Expertise

At Bombay Electricals, we possess extensive expertise in fabricating busbars, particularly working with copper and aluminium. Our proficiency includes understanding the unique technical requirements of these materials and delivering high-quality, reliable busbars.

Prototyping Capability

Our advanced prototyping capability allows us to provide quick samples of busbars, including copper busbars and electrical busbars, for evaluation. This ensures that our clients can assess the product’s suitability for their specific applications before full-scale production.

Raw Materials and Processes

Raw Material

- Electrolytic Tough Pitch (ETP) Grade Copper: We use high-quality ETP grade copper known for its excellent conductivity and durability

Fabrication Processes

We employ a range of precise and efficient fabrication processes to ensure the highest quality of busbars:

- Cutting: Precision cutting to exact specifications.

- Forming: Shaping the busbars to the required configurations.

- Punching/Drilling: Creating accurate holes and slots for connections.

- Slotting: Ensuring the proper fit and function within electrical systems.

- Bending: Custom bending to meet design requirements.

- Tapping: Preparing busbars for secure fastening.

- Plating: Providing Tin & Silver Plating for enhanced performance and corrosion resistance.

Customization and Delivery

Size Customization

We are capable of fabricating busbars in any size as per customer requirements. This customization ensures that our busbars fit perfectly into your electrical systems, providing optimal performance.

Prompt Delivery

Our unique selling proposition lies in our ability to deliver promptly. By optimizing our processes to save time and reduce costs, we ensure that our customers receive their busbars quickly and benefit from our efficient service.

FAQ’s

What materials are used in fabricated busbars?

Fabricated busbars are typically manufactured using high-conductivity copper or aluminum based on electrical and application requirements.

Are fabricated busbars custom manufactured?

Yes, fabricated busbars are manufactured as per drawings, dimensions and specifications to suit specific electrical applications.

Where are your fabricated busbars manufactured?

All fabricated busbars are manufactured at our facility in Mumbai, India.

What applications use fabricated busbars?

Fabricated busbars are widely used in transformers, switchgear, control panels and power distribution systems.